Flanges & Forgings: Ensuring Excellence at Every Step

At KPS Forge, we take immense pride in delivering flanges and forgings of unparalleled quality. Our commitment to excellence is deeply ingrained in every phase of our production process. Here’s how we ensure top-tier quality for our flanges and forgings:

Quality Assurance Process

Rigorous Inspections

Our flanges and forgings undergo meticulous inspections at every stage – from raw materials to the finished product. This ensures that each component meets the highest standards of precision, durability, and performance.

Expert Quality Team

Our experienced team of quality engineers, with an average experience of over 7 years, is capable of performing several Destructive Tests like Tensile Test, Impact Test, IGC Test, Micro/Macro Examination, Inclusion Rating, Hardness Test, etc., according to ASTM (American) and BS (British) standards. We have in-house testing facility to conduct the all above testing. However in addition, we do additional quality checks like HIC, SSC, Stress Rupture test etc. at reputed NABL laboratories.

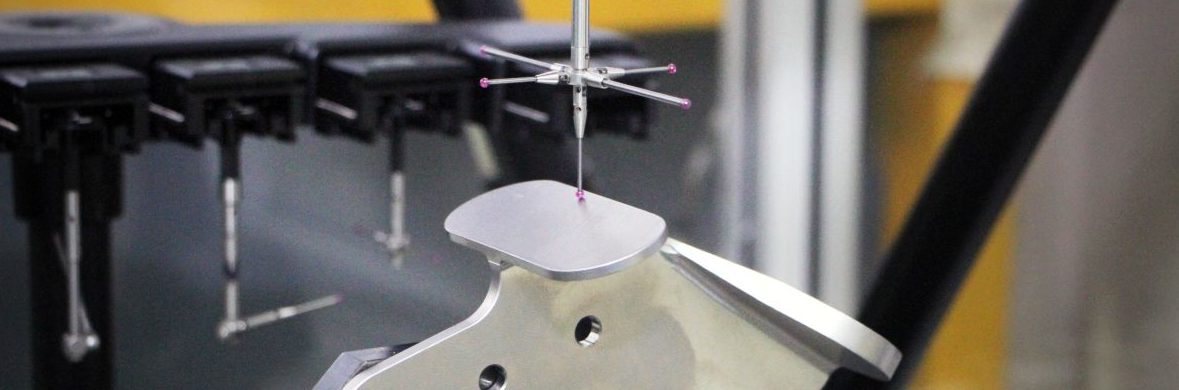

Non-Destructive Testing

We employ advanced non-destructive testing methods such as Ultrasonic Testing (UT), Magnetic Particle Testing, and Dye Penetrant Testing (DPT) to identify any imperfections or inconsistencies. This guarantees that our products exceed industry expectations. We have personnel certified as NDT Level II under ASNT SNT-TC-1A guidelines. Our Positive Material Identification (PMI) process provides reliable confirmation of the material involved.

Compliance with Codes and Standards

KPS Forge complies right from the design stage to testing, from material procurement to the delivery of the final product with National & International Codes/Standards, Quality Management System of ISO, and mandatory Indian Boiler Regulations. Our written procedures and work instructions cover every process, from raw material procurement to the dispatch of finished materials.

Third-Party Inspection (TPI)

KPS Forge has the capability to handle Third-Party Inspections (TPI) such as TUV, Lloyds Register, DNV, ABS, BVIS, etc., for EN 10204-3.2 certification.

We understand the importance of quality forged component. At KPS Forge, quality is at the core of everything we do. Our commitment to excellence is underlined by a range of internationally recognised certifications:

| SYSTEM CERTIFICATION | PRODUCT CERTIFICATION |

| ISO 9001 : 2015 – Quality Management System | PED 2014/68/EU & AD 2000 Merkblatt W0 |

| ISO 14001 : 2015 – Environmental Management | IBR Well Known Forge House |

| ISO 45001:2018 – Occupational Health & Safety | Canadian Registration Number (CRN) |

These certifications validate our commitment to delivering flanges and forgings of exceptional quality, conforming to international standards and regulations.

Your Partner in Quality

At KPS Forge, we go beyond manufacturing – we engineer excellence. Our quality assurance practices and certifications reflect our dedication to precision, durability, and customer satisfaction. Partner with us for flanges and forgings that redefine industry standards.

For inquiries about our quality assurance process, certifications, or to explore our flanges and forgings, please contact us.